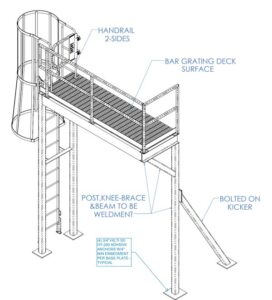

Recently, a customer contacted us with a problem. They needed a safe way to inspect and clear their conveyor chute. The plan was to fabricate an inspection platform, enclosed with railing, with a caged ladder for access. The top of the ladder would require a self-closing gate in order to meet OSHA requirements for guarding at ladder way openings, as the ladder was not offset from the platform.

Designing the Inspection Platform

As we started with concept drawings, we realized that the traditional fabrication of a post in each corner would not work with their application. The leading edge of the inspection platform extended into the aisle-way and a post in that corner would encroach on forklift traffic.

Upon consulting our PE, it was decided that we could use a short knee brace at the corner in question, and utilize a bolt-on kicker off the rear post for reinforcement. The kicker was designed to nest underneath their existing equipment.

As the installation location is open to the elements, and there is a high likelihood of debris, the inspection platform utilizes an open bar grating deck. This allows dirt and water to fall through the treads instead of collecting on top of a solid surface deck.

Platform Shipping and Installation

The inspection platform shipped knocked down for freight savings. A smaller load takes up less space on a truck and costs less to ship. It also allows for smaller, lighter pieces that are more easily maneuvered at tough to access locations. Installation required basic tools and no hot permit was required.

All components are designed for bolt together installation with basic hand tools. This eliminates the need for field welding, hot permits, and additional finish touchup around weld areas. Installation for the platform and ladder requires two men and one day. As the height is under 12 ft high, a forklift and A frame ladders or a scissor lift are all that are required for install.

With the new platform in place, this customer can now safely inspect and perform maintenance on their chute at any time without impeding regular business activity in the area. Fabrication lead time for the platform, ladder, and gate was quoted at 5-7 weeks after approved drawings were returned. The material was shipped at right on time at 5 weeks. Pricing was also what the original estimate was. On time. On budget. Contact A-Mezz for help with your next project.