An old lift out gate in the wild.

I have a confession to make. I really don’t like lift out gates. Every time a customer asks me to put in a lift out gate on their platform, I get a sour taste in my mouth. Today I want to talk a little about why I dislike them so much, and what other options exist.

Why I Dislike Lift Out Gates

My beef with lift out gates largely boils down to one thing: safety. Lift out gate are surprisingly heavy. A 6′ wide lift out weldment weighs approximately 180 lbs. They are large weldments and can be removed with a forklift. Asking your employees to remove one by hand is asking them to stand over the edge of the abyss and lift up an anchor. It’s just not a safe option.

If you are not removing them by forklift, there are a few things you can do to minimize the risk. Your workers should tie off anytime they are manually removing or replacing the gate. They should grab a partner and lift the gate out in pairs. If at all possible, I’d also recommend keeping the individual gates under 4′ wide each. The best thing we can do though, is recommend a different gate solution.

What Might Work Better

There are typically two main reasons why customers ask for a lift out gate: price and access. Let’s look at these reasons and see if there’s something better we can recommend.

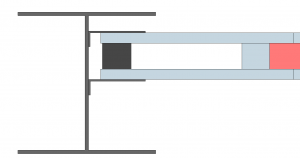

A bi-parting swing gate like this would be safer and more cost effective then two small lift out sections of railing.

Probably the most common reason customers ask for a lift out gate is price. They are hoping to save a buck and go with the least expensive option. A single lift out gate is the least expensive gate we can offer, but not by much. A 6′ bi-parting swing gate is only a couple hundred dollars more than a single 6′ lift out gate, and is actually less expensive than a pair of 3′ wide lift out gates. When looking at the overall cost of the platform, this is an extremely minor difference. If you have the space available, our standard pivoting mezzanine safety gate is only a couple hundred dollars more than the bi-parting swing gate and will always keep a line of safety railing between your workers and the edge. If you’re trying to keep costs down as much as possible, these are the two gates I’d be looking at.

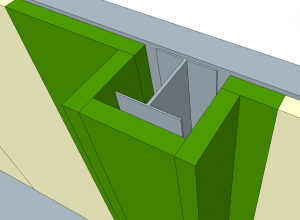

A vertical lifting mezzanine gate like this can have up to a 16′ clear opening, and we can set them up to share columns if you were hoping to have access across multiple adjacent bays.

Most of the other times a customer is requesting lift out gates, it has something to do with the flexibility of the access. Perhaps they have something fairly large that they will need to put up on the deck. We can do a vertical lifting mezzanine gate that has a clear opening up to 16′ wide. Perhaps the customer wanted to be able to access all across the front of the platform as opposed to funneling everything through one or two gate openings. There is nothing stopping us from adding more gates all along the front.

Removable Railings

Sure we could do a removable rail using lift out gates, but these weldments are heavy and the price adds up quickly.

The only time we couldn’t solve the access issue with more gates or longer gates is if the object the customer is sending through the gate is longer than 16′. If this is a frequent occurrence and you’re not able to crane the material onto the deck, then a line of lift out gates would be the best solution we currently have to offer.

But what if this is one of those “blue moon” occurrences? In this case, I would recommend you forgo the lift out gates and save yourself a significant amount of money. Our typical 2-rail handrail is composed of hoops that are screwed into clips on uprights roughly every 8′. You can unscrew the hoops from the saddle clips. You can unbolt the uprights from the face of the mezzanine. We can design the railing to utilize smaller hoops so it’s easier to lift out individual sections. We can change our kick plate so it connects the uprights as opposed to the framing below the decking. This way it’s not too difficult to remove and reattach the railing should you need to without the added expense of all the weldment sections.

So next time you’re thinking of putting in a lift out gate, let’s discuss it and see if we might be able to come up with a better solution.