Regardless of how much training you’ve had, or how careful you are, accidents can happen. Even your best fork truck driver can make a mistake. I recently had a customer contact me with just such a situation.

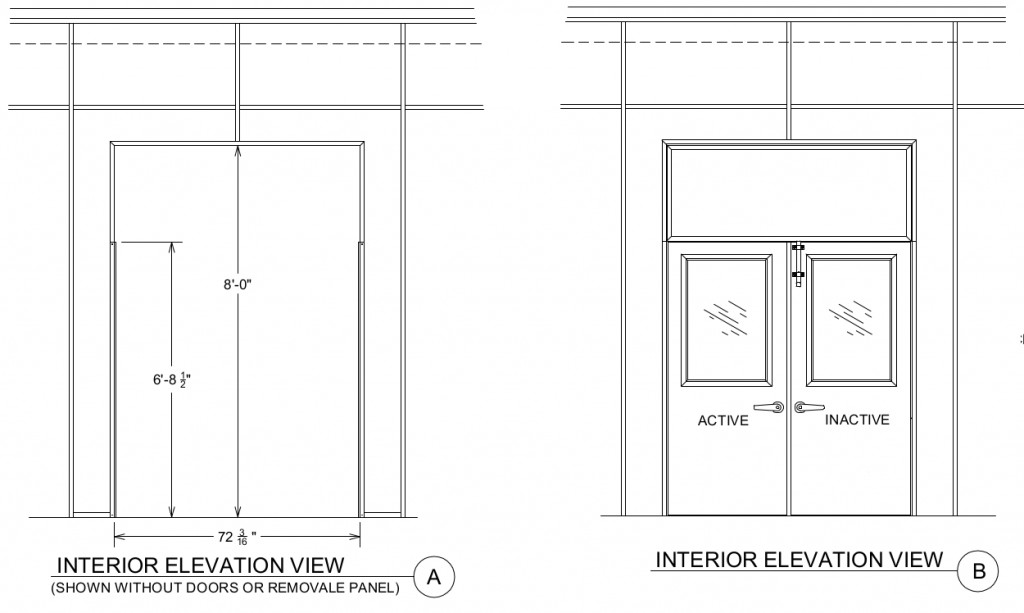

Last year the customer had put in a quality assurance lab and office using our A-wall modular building system. Unfortunately, their best fork truck driver slipped up and ran into the wall. They were lucky: no one was injured, and he was able to stop before he caused any significant structural damage. It did however knock a knock a 2”x4” hole on the one side of the wall panel and a larger hole on the inside where it pushed through. Since the damage was localized to a couple small holes in a single panel and there was no structural damage to any of the other components, the customer contacted a local drywall contractor to repair the damage to the panel, and we were able to provide him with a sheet of vinyl to cover the patches with.

This all could have been avoided if the customer put up a line of industrial guardrail around the perimeter. Our industrial guardrail is available in single and double rail configurations, and our standard non-liftout system is designed for a 10,000 lb at 4 mph breakthrough. It’s bolt together design is easy to install and comes with all required hardware, including the concrete anchors. We offer a wide variety of lengths and off-center welded baseplates to configure a layout that will best fit your facility’s layout. We can even provide you with a heavy duty gate system that can stop a 13,500 lb fork truck moving at 6.5 mph, yet fold out of the wall to allow passage. Next time you’re thinking about putting in a structure in an area with fork traffic, don’t forget about adding guardrail to protect your workers and your equipment. You might not be as lucky as this customer was.