CMM, or coordinate measuring machines, are a piece of equipment that uses a physical or laser probe to map out the geography of an object. They are very precise machines and need to be kept in a clean and often temperature controlled environment. I recently had a customer who found this out the hard way when the dust in the air due to production was messing with his machine, so he contacted us looking for an equipment enclosure.

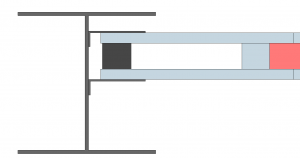

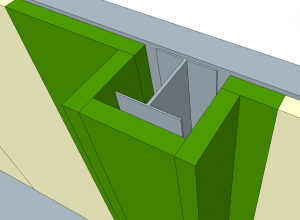

Using modular building panels, we designed a 16′ deep by 20′ wide four wall enclosure. Due to the maximum height of the mast on the CMM, the customer needed a lot of available head room in the area, so we stacked panels up to 13′ using the A-wall 300 system, leaving us 12’6″ of available head room under the drop ceiling and recessed lights. The customer wanted a way to easily remove the CMM if he needed to in the future, but didn’t want to put in a large door. In order to facilitate this, we put in a 8′ wide by 9′ high removable panel assembly using a tubular steel “goal post” and some additional trim pieces, so if he did need to move the equipment he would just need to remove the extra trim pieces on the outside and pop put the panels. The customer wanted a lot of windows in the enclosure, and since the A-Wall modular building system’s windows are factory installed right into the panel as a single piece, we were able to put one in every 4′ panel (aside from the one with the HVAC system) that wasn’t facing their wall, including the two removable panels. We also outfitted the room with Flex-4 modular wiring inside the wall panels in order to save the customer money on the electrical installation.

Upon contacting us, the customer was looking for a quick solution. After receiving the order we were able to send him approval drawings the next day. He was able to quickly turn around the approved drawings so we were able to ship it out to him in two weeks. The installation took a two man crew two days to complete. Twenty two days after we received the PO, the customer had this great looking equipment enclosure assisting with the smooth operation of the CMM.